MetalWorm

Robotic Wire Arc

Additive Manufacturing System

Products

Technology

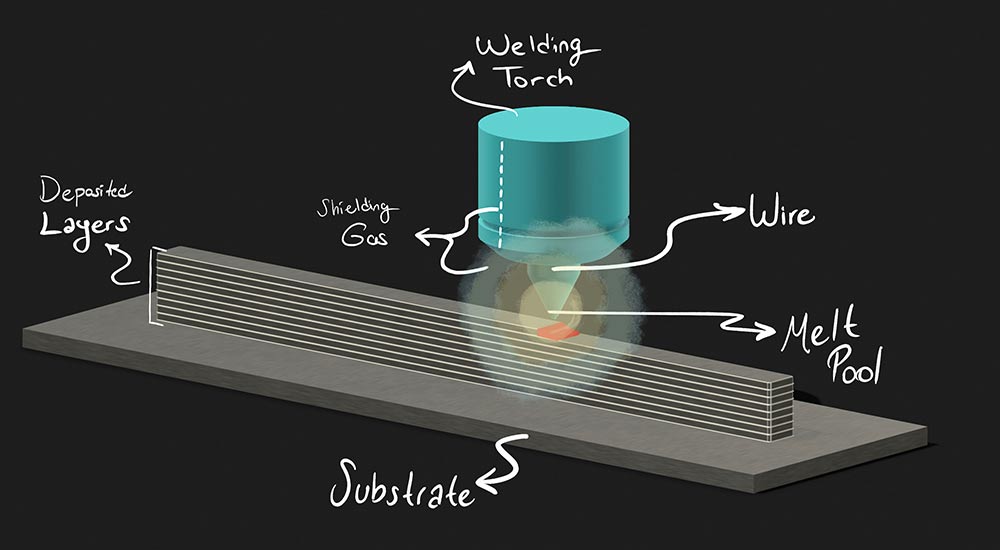

Robotic WAAM Technology

Wire Arc Additive Manufacturing (WAAM) is an advanced manufacturing technique used to build ……

High Deposition Rates

WAAM is known for its relatively high deposition rates compared to other metal additive manufacturing processes. This makes it suitable for manufacturing large-scale components or structures.

High Deposition Rates

WAAM can utilize a wide range of metal materials in wire form, including stainless steel, aluminum, invar, and their alloys. This versatility makes it applicable across various industries, including aerospace, oil & gas, and maritime.

Cost-effectiveness

The use of wire as feedstock can be more cost-effective compared to other forms of metal feedstock such as powders. This can be advantageous for industries where cost efficiency is a significant factor.

Repair and Modification

WAAM can also be used for repair and modification of existing components, allowing for cost-effective and efficient repair of high-value parts.

Software

Provides real-time monitoring of the entire system and offers a unique digital twin solution. This way, you can monitor and control the entire system and production process from end to end.

Blogs

Aprenda WAAM?

A fabricação aditiva está revolucionando o cenário de produção ao oferecer métodos inovadores para criar componentes complexos. Dentre esses, a Fabricacão Aditiva por Arco

Aprender WAAM?

La fabricación aditiva está revolucionando el panorama de la producción al ofrecer métodos innovadores para crear componentes complejos. Entre estos, la Fabricación Aditiva po

What's new?

MetalWorm Expands to Southeast Asia with First WAAM System in Malaysia

Exciting News from MetalWorm! We’re proud to announce the successful sale and upcoming installation of a Robotic Wire Arc Additive Manufacturing (WAAM) system in Malaysia, delive

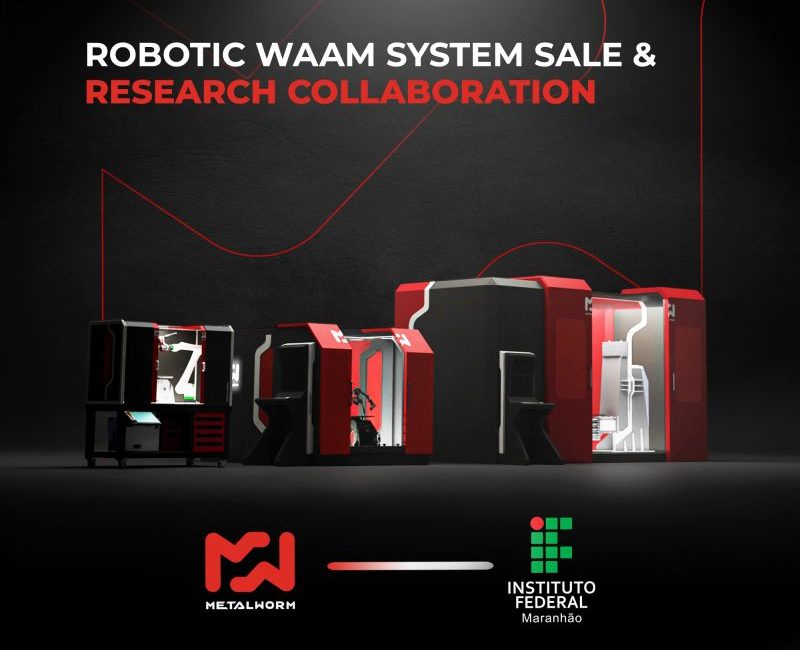

MetalWorm’s WAAM Technology is Now in Brazil!

MetalWorm’s WAAM Technology is Now in Brazil! One of Brazil’s leading technical institutions, #IFMA (Instituto Federal do Maranhão), has chosen #MetalWorm’s Robotic #WAAM (W

MetalWorm Showcases Latest WAAM Innovations and Industry-Academia Collaborations at AMC 2025 Conference

The AMC 2025 Conference has officially kicked off with great participation between April 28–30! We are proud to represent MetalWorm at this important event. With many distinguish